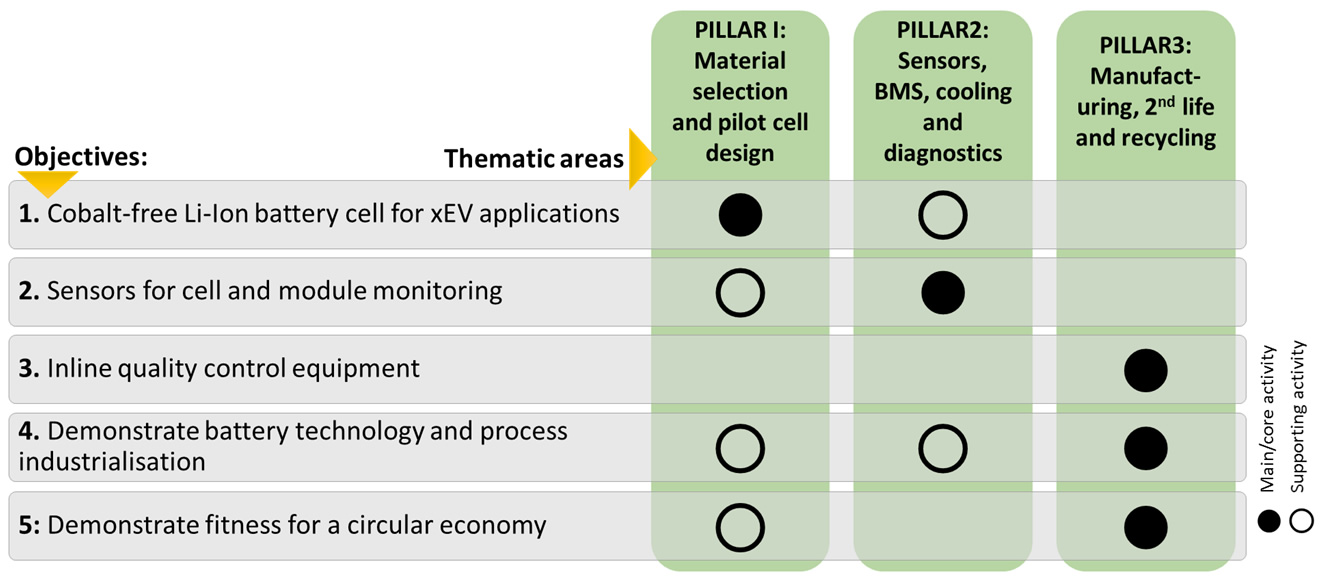

The overall aim of 3beLiEVe is to develop and demonstrate production of the next-generation (generation 3b) of high-energy LNMO cells with sensors suitable for xEV applications and compatible with a circular economy, as well as to demonstrate European manufacturing capability to cover the whole value chain from cell to system level. The project aims to respond to all objectives set in the LC-BAT-5-2019 topic. To this end, the overall aim is broken down into five key objectives across three thematic pillars. The objectives are:

About 3beLiEVe

Project objectives

Project keywords

3b Generation

3beLiEVe contributes to advances in the field of advanced Li-ion technologies, specifically generation 3b according to the EU’s Integrated SET Plan (batteries and e-mobility). Gen 3b cells are expected to be commercially available around 2025, and should be the final generation before all-solid-state batteries.

Smart Sensors

More rapid and detailed knowledge of the internal state of a cell can help to improve operating strategies, for example charging and cooling, to slow down battery ageing and increase safety. This should extend cell life, increase user acceptance, allow determination of the cell’s suitability for uses beyond the first life, and so reduce the cell’s cost over an extended lifecycle.

Circular Economy

Designing a battery to reduce the use of critical raw materials, make it easy to reuse in a second life, and to recycle at the end of its useful life is critical towards supporting a circular economy. 3beLiEVe integrates these aspects into its design process right from the start. Lifecycle analysis will reveal environmental impacts and financial costs.

Manufacturing

Manufacturing quality of electrodes and cells has an impact on the performance, lifetime and safety of the battery. 3beLiEVe will examine the quality of electrode coating using a special camera, and will classify defects using machine learning techniques. The project will also explore novel manufacturing materials and techniques for casings and cooling systems.

2nd Life

To make a battery attractive for an application after its first life in cars, buses or trucks, it needs to be easy to reconfigure to a new purpose. 3beLiEVe will assess what information needs to be available for this, as well as battery performance and costs when used as stationary energy storage combined with a photovoltaic (solar) power plant in an island electric grid.

Recycling

Even the best battery will one day reach the end of its usability. To recover materials, save energy and minimize waste, it should be recycled. The 3beLiEVe design aims to facilitate a high materials recovery and purity through materials selection and design for easy disassembly in the design stage.

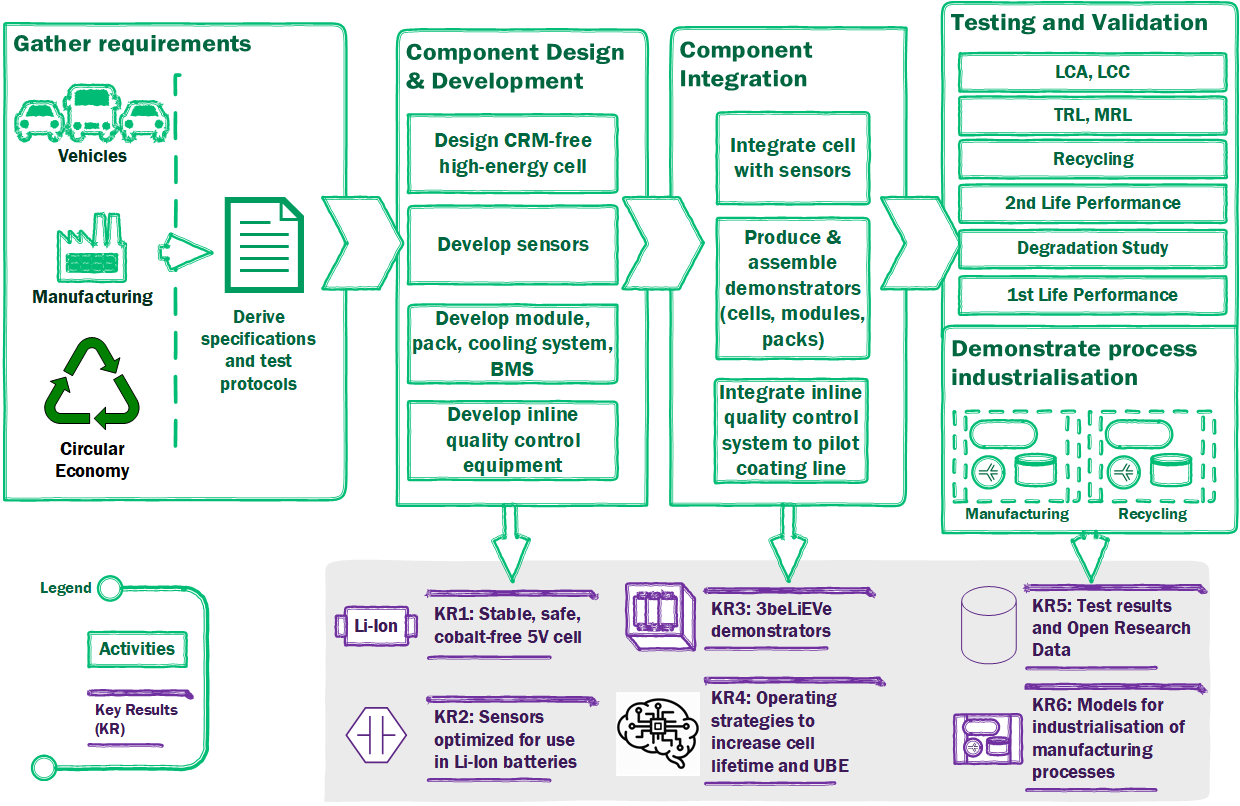

Project steps

The project activities are encapsulated in the following work packages:

- WP1– Technical requirements and specifications

- WP2– Materials selection for 3beLiEVe battery cells

- WP3–Cell architecture design and prototyping of the pilot cells

- WP4–Design and development of sensors, cooling, smart BMS, module and pack

- WP5–Advanced manufacturing methods and equipment

- WP6–Production of the 3beLiEVe cells, modules and demonstrator packs

- WP7–Testing, qualification and ex-post assessment

- WP8–Dissemination, Communication, IPR management and Exploitation

- WP9–Project Management